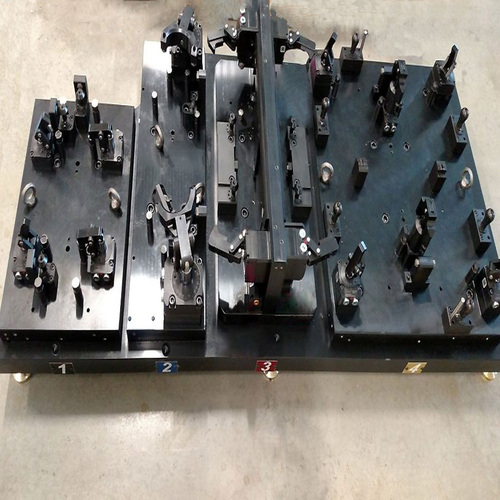

About Steel Jigs And Fixtures

Steel jigs and fixtures are tools used in manufacturing and production processes to hold, support, or position parts during machining, assembly, or other operations. They are integral to ensuring precision, repeatability, and efficiency in the production of parts, especially in mass production or highly complex assembly lines.

Here a breakdown of what they are and how they are used:

Jigs:

- Function: A jig is a tool that holds and positions a workpiece in place during machining, drilling, or other processes. It may also guide the cutting tool (like a drill bit or mill) to ensure precise cuts or holes in the correct position.

- Key Feature: Jigs typically have built-in guides that direct the tool, ensuring that the workpiece is cut or drilled in the same position each time.

- Examples: A drilling jig, used to drill holes at precise locations on a workpiece, or a welding jig, which ensures parts are aligned before welding.

Fixtures:

- Function: A fixture holds the workpiece securely in place during machining or assembly operations. It does not guide the cutting tool like a jig but instead ensures the work piece is positioned correctly and does not move during the operation.

- Key Feature: Fixtures are often more complex than jigs, especially when they need to hold large or irregularly shaped parts.

- Examples: A fixture could be used in milling or CNC operations, where it holds the workpiece while a machine performs cuts or processes on it.

Steel Material Benefits:

Steel is commonly used for jigs and fixtures due to its strength, durability, and rigidity. The material can withstand heavy loads and forces during operations without deforming, which ensures high accuracy in the final product. Some of the benefits of using steel for these tools include:

- Strength and Rigidity: Steel can handle the stresses of holding large or heavy workpieces, making it ideal for high-force machining or heavy-duty assembly.

- Durability: Steel jigs and fixtures are highly durable and can last through thousands or even millions of cycles.

- Wear Resistance: Steel, especially alloy steels or hardened steel, can resist wear and tear from repeated contact with workpieces and tools.

- Thermal Stability: Steel retains its properties well under a wide range of temperatures, which is crucial for certain machining processes.

Types of Steel Used:

- Mild Steel: Often used for general-purpose fixtures where high strength is not as critical.

- Alloy Steel: Used for fixtures and jigs that need higher strength, hardness, and resistance to wear.

- Tool Steel: Used when extreme durability and hardness are required, especially in jigs or fixtures exposed to high-stress machining environments.

Applications:

- Precision Machining: Steel jigs and fixtures are commonly used in CNC machining, turning, drilling, grinding, and milling operations to maintain accuracy and repeatability.

- Welding and Assembly: In industries like automotive manufacturing, steel jigs and fixtures help ensure precise alignment and positioning during welding or assembly processes.

- Mass Production: For industries that rely on high-volume manufacturing, steel jigs and fixtures help produce parts at scale with consistent quality.

Are you considering using jigs and fixtures in a particular project or industry? Let me know, and I can offer more tailored info!